Save on Laser Cutting with In...

Stock & Remnant Sheet Metal

To save on laser cutting, MS Laser Services combines CNC precision with smart material use — including in-stock metal sheets, pre-cut sizes, and remnants. Whether you’re ordering a one-off laser cutting service or a short production run, using our stocked materials is the most cost-effective route.

Why Our Stock Metal Saves you money

- No full sheet required – we only use what you need

- Faster turnaround – Materials already in-house

- Smaller deliveries – Cheaper shippingr

- Transparent quotes – cut time + Material price, no surprises

Save money on laser cutting by avoiding full-sheet costs.

What you’ll find on our group sites:

A wide choice of metals and surface finishes

Standard sheet sizes and thicknesses

Transparent pricing — see the cost before you enquire

You don’t need to purchase the sheet — it’s simply to explore what’s available and estimate the material cost.

Stock, Pre-Cut & Remnant Sheet Metal Sources

Our group operates two online sheet metal stores and we have remnants:

- MetalOffCuts.co.uk – pre-cut sheet sizes

- Sheet Remnants –We hold a varied stock of odd-sized offcuts ideal for small parts, though not listed online.

Our remnant stock (not listed online) is ideal for small jobs and prototypes — and offers the best savings when only a small quantity is needed.

MetalSheets.co.uk/shop – full sheet stock for larger projects

What Affects Cost When You Want to Save on Laser Cutting?

While sheet prices are visible online, your actual laser cutting quote depends on:

-

Your DXF or DWG file – required for accurate quoting

-

Quantity of parts – bulk cutting often reduces per-part cost

-

Nesting & kerf spacing – we allow for laser path clearance and sheet edge margins

-

Metal type & thickness – different materials cut at different speeds

-

Optional finishing – such as deburring, patina, or lacquer

Why You Can Save on Laser Cutting with In-Stock Sheet Metal

At MS Laser Services, we believe great design shouldn’t come with unnecessary costs or complications. That’s why we make it easy to bring your ideas to life — without having to buy a full sheet of metal you don’t need. We only use exactly what your design requires, saving you money and cutting down on waste.

Because we keep a wide variety of popular metals in stock, your project can get underway right away — meaning faster turnaround times and less waiting around. And since smaller, lighter deliveries are easier to handle, you’ll also enjoy cheaper shipping and a smoother, more sustainable process from start to finish.

We know how frustrating hidden costs can be, so our quotes are always clear, honest, and transparent. What you see is what you pay — no surprises, no fine print. Whether you’re a maker testing a new design, a business creating custom parts, or an artist crafting something unique, our goal is to make the laser cutting experience as simple, stress-free, and inspiring as possible.

Can I Still Save on Laser Cutting if My Metal Isn’t Listed?

We’ll give you a quick, transparent quote to save money on laser cutting using our stocked metals

Even if your preferred size or finish isn’t listed in our online shops:

We’re happy to discuss options — just get in touch.

Call us on 0151 526 4777 or email info@mslaserservices.co.uk — we’re happy to advise.

For jobs that require tighter tolerances or intricate detailing, our precision sheet metal cutting service provides the accuracy needed for production-quality components.

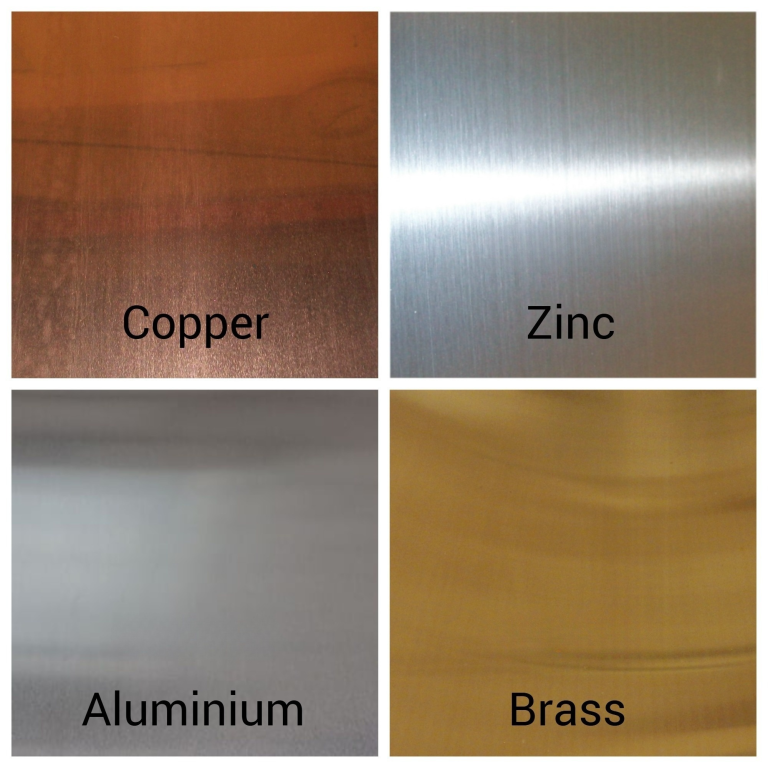

Many customers save money simply by choosing the right material. You can see the full range of metals we keep in stock on our sheet metal materials page, including aluminium, stainless steel, brass, copper, zinc and Corten.

If your project includes tags, branding plates or small signage elements, our laser cut signs page shows how we handle intricate lettering and decorative components.

For prototypes and small-format parts, you can reduce material costs even further with our laser cutting with remnants service — ideal when your job doesn’t require a full sheet.

Working with thin or lightweight materials? Our dedicated 1mm aluminium laser cutting service provides clean, accurate cuts for panels, tags and lightweight components.

If you’re unsure which metal offers the best balance of price and performance, our guide to metals for laser cutting explains the strengths, limitations and best-use cases of each material.

Ready to Save on Laser Cutting with off the shelf metal?

Send your file and material choice — we’ll give you a quick, transparent quote.

Whether you’re ordering a one-off component or need ongoing production, we offer fast, affordable laser cutting with flexible fulfilment.

Need unbranded fulfilment for trade or retail clients? We also provide white label cutting services — perfect for designers, signage firms, and OEMs who want expert cutting without our branding.

Yes. We accept DXF and DWG files — just upload your design along with your chosen metal type or finish.

Visit MetalOffcuts.co.uk for pre-cut sizes or MetalSheets.co.uk for full sheets. Prices are listed online, with no obligation to buy — perfect for estimating costs.

We base your quote on cutting time, setup time, and material cost from our stock — plus delivery. You only pay for the material used.

Yes. Please allow 3–5mm spacing between components and from the sheet edge to ensure a clean, accurate cut. Ask us if in doubt.

Absolutely. It’s the best way to save on laser cutting — no full sheet purchase needed, and faster turnaround from in-house stock.

No problem — we can usually source it the next working day. You can also provide your own material, depending on its suitability for laser cutting.

Yes. We keep a wide range of remnant sheet metal ideal for prototypes and small parts. These aren’t listed online — just ask when you enquire.