Laser Cutting & Profiling for Sheet Metal in Liverpool

Thin-gauge sheet metal laser cutting in Liverpool and UK-wide — fast quotes, 0.5–3.0 mm cutting, and no minimum order from MS Laser Services.

At MS Laser Services, we specialise in thin-gauge laser cutting and profiling for stainless steel, aluminium, brass, copper, zinc and more. Our 3 kW fibre laser delivers clean, accurate cuts from 0.5 mm to 3.0 mm, with a full 3 m × 1.5 m bed size suitable for prototypes, short runs and production batches. Same-day quotes, fast turnaround, and nationwide delivery from our Liverpool workshop.

Thin-Gauge Sheet Metal Laser Cutting — Fast quotes, 0.5–3.0 mm cutting, no minimum order.

Why Choose Our Laser Cutting Service?

Specialists in thin-gauge sheet metal (0.5–3.0 mm)

3 m × 1.5 m fibre laser — ideal for prototypes and batch production

Same-day quotes and typical 2–5 day turnaround

No minimum order — one-offs to small runs welcome

In-house CAD support

Cost-saving remnant / part-sheet options

UK-sourced materials wherever possible

Friendly team, consistent edge quality, fast fulfilment

Who Uses Our Laser Cutting Service

Sign makers & branding studios — letters, plaques, folded trays

→ See our laser cut signage

Architectural metalworkers — cladding panels, screens, inlays

Interior designers & shopfitters — fascias, feature panels, branding details

OEMs & industrial clients — bracketry, faceplates, covers, components

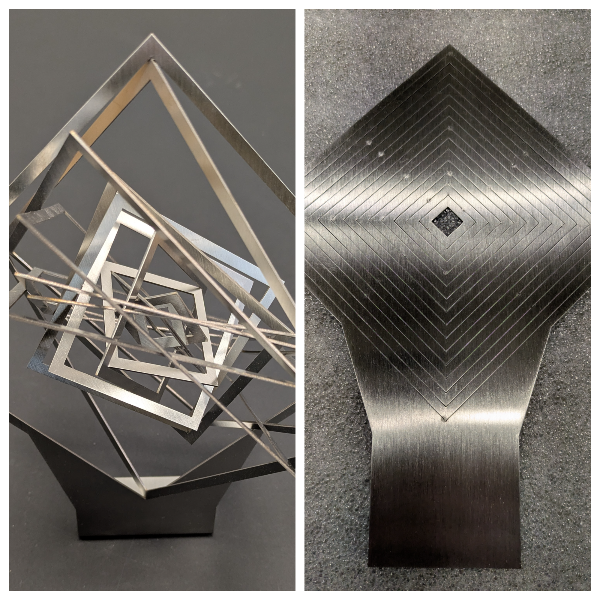

Our fibre laser delivers clean edges, tight tolerances and consistent repeatability, ensuring every detail comes out sharp — from intricate patterns to large architectural pieces.

We also offer a white-label cutting service for trade clients who need unbranded production under their own name, helping designers, agencies and signage firms scale without adding fabrication capacity.

Materials We Cut with Our Laser Cutting Service

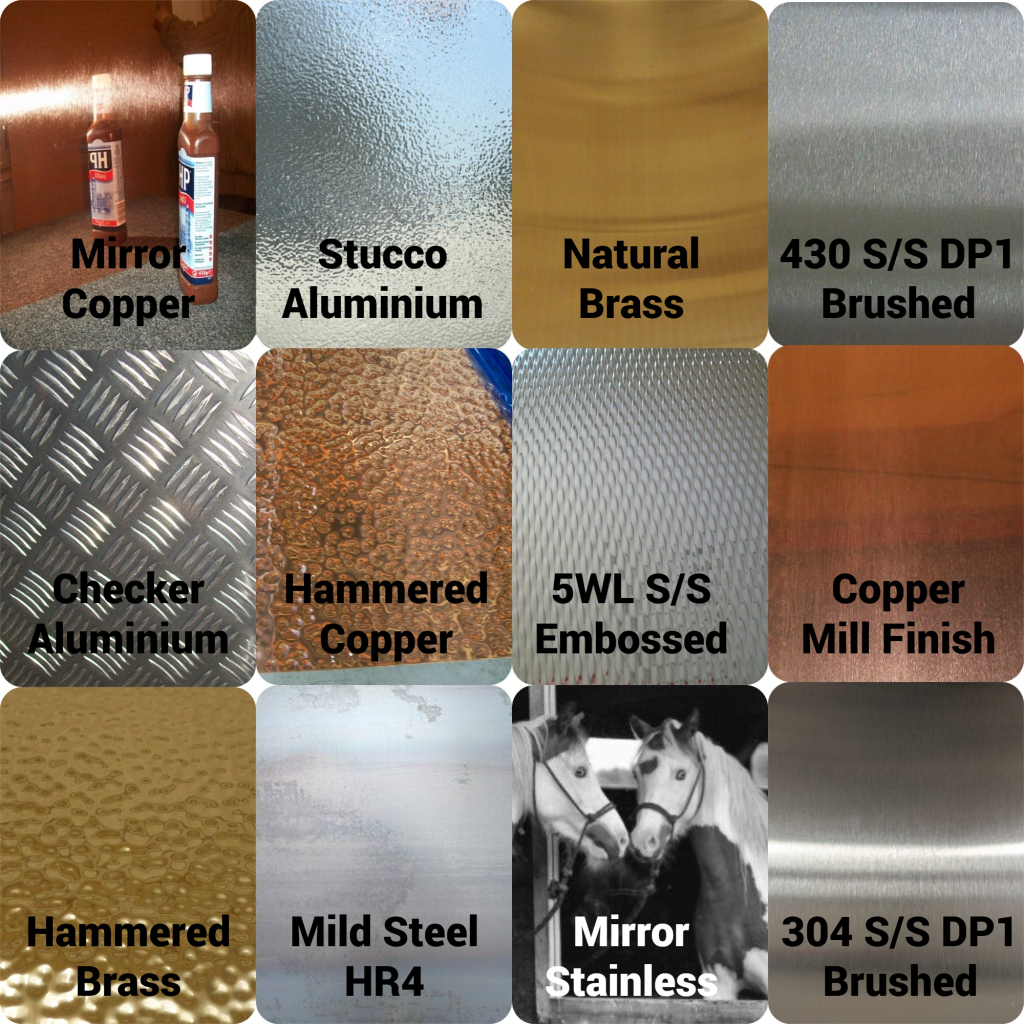

We cut a wide range of metals in-house, with most grades and finishes kept in stock. Part-sheets and remnants are available to help reduce material waste on small or efficient nests.

Stainless Steel – 304 & 316 in Brushed (DP1), Mirror Polished, 2B, and Squares

Aluminium – 1050A, 5754 checker plate, available in Natural, Anodised, Brushed, Polished, and Stucco

Brass – CZ108 and CZ120 in Natural, Polished, Brushed, and Hammered finishes

Copper – Natural (mill), Mirror Polished, Brushed, and Hammered

Zinc – Natural (semi-bright), Preweathered, Light Patina, and Antique Patina

Mild Steel – CR4 (cold rolled), HR4 (hot rolled), Zintec-coated, and Galvanised

Corten Steel – Natural (ready to rust) or Pre-rusted finish

We stock popular sizes and can cut both full sheets and offcuts to suit small jobs or prototypes. Customers can also purchase part sheets to reduce material costs on smaller or more efficient layouts.

We prioritise UK-sourced materials wherever possible. (See more about UK manufacturing initiatives.)

See our laser in action…

See our fibre laser in action as it cuts brass into detailed decorative panels with exceptional speed and precision. This short video shows the clean edges, tight tolerances and smooth curves achievable on thin-gauge metals — ideal for signage, architectural features, and custom design work. A quick look at the consistent quality that designers, fabricators and contractors rely on every day.

Additional Laser Cutting Options

For parts requiring tight tolerances or intricate detail, our precision sheet metal cutting service is ideal for prototypes, repeat components and architectural work.

We also produce laser cut perforated panels in brass, copper, stainless steel and aluminium for screens, grilles and feature panels.

To see all the metals we keep in stock, visit our sheet metal materials page, covering brass, copper, stainless steel, aluminium, zinc, Corten and more.

Looking to reduce costs on smaller batches or one-off parts? Our laser cutting with remnants option uses in-house part sheets for more economical pricing.

For lightweight signage, tags and covers, we offer dedicated laser cutting for 1 mm aluminium, ensuring clean edges and minimal distortion on thin-gauge material.

Not sure which metal is best for your project? Our guide to metals for laser cutting explains the strengths and limitations of each material to help you choose with confidence.

Pricing & Lead Times for Laser Cutting

We provide clear, itemised pricing for one-off parts, prototypes and batch production. Every quote is based on:

Material type & thickness

Cut time (speed, length, complexity)

Nesting efficiency

Quantity / repeatability

Most projects are completed within 2–5 working days, and smaller urgent jobs can often be turned around next-day. Using remnants or part-sheet stock can significantly reduce material costs.

Email your drawings for a fast quote, or upload your file using the form — we’ll respond quickly with transparent pricing and lead time.

.

Nationwide Delivery

We ship laser-cut metal nationwide via Royal Mail, DHL and Fortec, with dedicated courier options for fragile or high-value work.

Ready to Save on Laser Cutting with off the shelf metal?

Send your file and material choice — we’ll give you a quick, transparent quote.

Whether you’re ordering a one-off component or need ongoing production, we offer fast, affordable laser cutting with flexible fulfilment.

Need unbranded fulfilment for trade or retail clients? We also provide white label cutting services — perfect for designers, signage firms, and OEMs who want expert cutting without our branding.

Frequently Asked Questions

Yes. We accept DXF and DWG files — just upload your design along with your chosen metal type or finish.

Visit MetalOffcuts.co.uk for pre-cut sizes or MetalSheets.co.uk for full sheets. Prices are listed online, with no obligation to buy — perfect for estimating costs.

Yes. Please allow 3–5mm spacing between components and from the sheet edge to ensure a clean, accurate cut. Ask us if in doubt.

We base your quote on cutting time, setup time, and material cost from our stock — plus delivery. You only pay for the material used.

Absolutely. It’s the best way to save on laser cutting — no full sheet purchase needed, and faster turnaround from in-house stock.

No problem — we can usually source it the next working day. You can also provide your own material, depending on its suitability for laser cutting.

Yes. We keep a wide range of remnant sheet metal ideal for prototypes and small parts. These aren’t listed online — just ask when you enquire.