A Guide to Metals for Laser Cutting

Choosing the right metals for laser cutting can make all the difference.

In this guide to metals for laser cutting, we explore how aluminium, stainless steel, copper, brass, zinc, Corten, and mild steel each perform under the laser — and when they’re the ideal choice for your project.

Every metal offers its own unique balance of strength, finish, and cutting characteristics, influencing everything from edge quality to design detail.

Whether you’re creating precision components, decorative panels, or custom signage, understanding these differences helps you achieve the best results every time.

At MS Laser Services, our experienced team is here to help you select the perfect material and optimise your design for accuracy, efficiency, and visual appeal — ensuring your project looks exceptional and performs flawlessly.

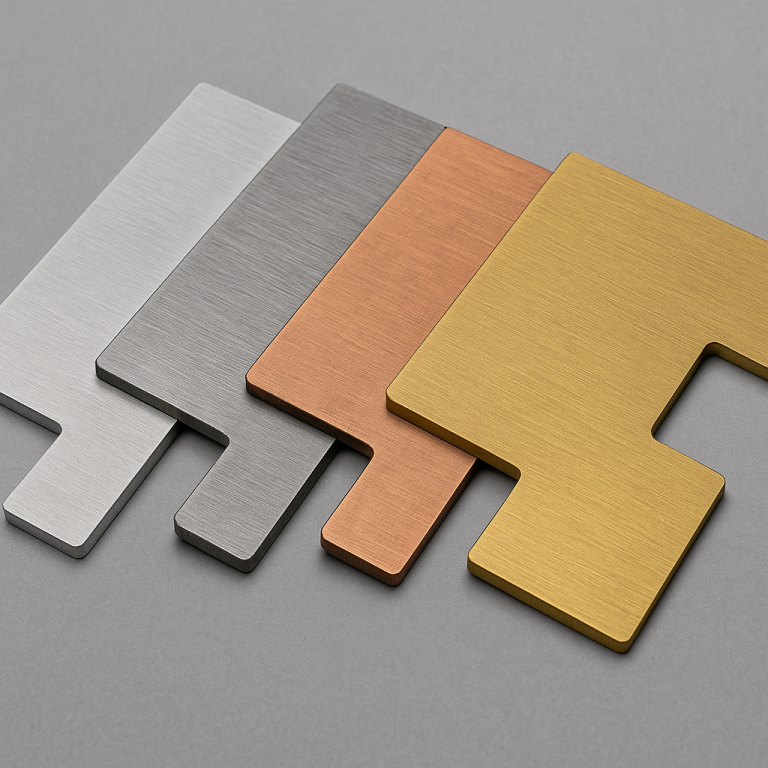

Laser cut samples of aluminium stainless steel copper and brass showcasing different finishes and materials we work with at MS Laser Services

Laser Cutting Copper – Durable & Aesthetic

Key Benefits:

- Corrosion-resistant

- Excellent electrical conductivity

- Develops a rich, natural patina over time

Common Uses:

- Signage

- Interior accents

- Decorative elements

- Electrical components

Note: Copper is reflective, which can cause laser beam bounce-back and damage optics. We adjust settings carefully and stock thin copper sheet for safe, clean cutting.

For insight on how fibre lasers overcome this challenge, see this detailed guide: [Cutting Copper on Laser: Challenges, Techniques, and Innovations]

Laser Cutting Brass – Elegant & Corrosion-Resistant

Key Benefits:

- High-end visual appeal

- Easy to engrave or cut

- Strong resistance to tarnishing

Common Uses:

- Plaques and nameplates

- Bar tops and trims

- Retail signage and branding

- Decorative cladding

We offer various brass finishes including mirror polished, brushed, and patinated.

Laser Cutting Zinc – Lightweight & Patina-Friendly

Key Benefits:

- Develops a self-healing patina

- Lightweight and workable

- Naturall corrosion-resistant

Common Uses:

- Countertops

- Cladding

- Bath Panels

- Wayfinding signs

Zinc is ideal for rustic or industrial-style finishes and folds cleanly in press braking.

Laser Cutting Stainless Steel- Strong & Modern

Key Benefits:

- Durable and corrosion-resistant

- Fire and Heat resistant

- Clean industrial appearance

Common Uses:

- Sign trays

- Food-grade applications

- Fascias and wall panels

- Public-facing signage

Available in brushed (DP1), mirror polished, 2B, and patterned finishes.

Laser Cutting Corten Steel- Industrial & weathered

Key Benefits:

- Naturally develops a protective rust-like patina

- Low maintenance

- Strong visual impact

Common Uses:

- Outdoor signage

- Planters

- Garden sculptures

- Branding panels

Cut raw or pre-weathered; requires care when designing for clean lettering.

Laser Cutting Aluminium- Lightweight & Versatile

Key Benefits:

- Corrosion-resistant

- Lightweight and economical

- Suitable for indoor and outdoor use

Common Uses:

- Architectural detailing

- Custom cut panels

- Control boxes

- Logos and parts

We stock aluminium in mill finish, brushed, polished, anodised, checker, and stucco.

Laser Cutting Galvanised & Mild Steel

Galvanised Steel

Zinc-coated for corrosion resistance — ideal for enclosures and outdoor parts.

Mild Steel

Cost-effective and easy to weld — used for structural brackets, frames, and base components.

We stock both in multiple thicknesses, including CR4, hot rolled, Zintec, and galvanised variants.

Pricing Guidance

Pricing for our laser cutting services varies by material and complexity. For example, cutting simple 1 mm thick parts starts from £25.00 + material. We’re happy to advise on the most cost-effective sheet and finish for your project.

If you’re ready to turn your material choice into finished parts, our thin-gauge laser cutting service provides clean, accurate profiling across all of the metals discussed in this guide.

For components that demand tight tolerances or small intricate features, our precision sheet metal cutting service ensures consistent results from prototypes through to production runs.

Many of these materials are also used for branding plates and architectural details. Visit our laser cut signs page for examples in brass, copper, stainless steel, aluminium, zinc and Corten.

To see which metals we hold in stock — from aluminium and stainless steel to brass, copper and zinc — view our sheet metal materials page.

If you’re producing prototypes or small-format parts, our laser cutting with remnants option can offer a more economical route while maintaining the same clean edge quality.

Working specifically with aluminium? Our dedicated page on laser cutting 1mm aluminium covers tolerances, finish options and best practices for thin-gauge sheet.

Aluminium and mild steel are generally the easiest metals for laser cutting. Both produce clean edges, cut quickly, and are cost-effective choices for most projects.

Yes. We laser cut thin-gauge copper and brass using fibre laser technology. These metals are reflective, so special settings are used to achieve safe, accurate cuts with high-quality edges.

Absolutely. Each material — aluminium, stainless steel, copper, brass, zinc, Corten, or mild steel — requires unique cutting speeds, power levels, and gas assist to ensure the best finish and precision.